In

December of 1987 Max moved to Montana with his family to build Varga airplanes

again. His first task was to modernize the design. The following pictures are

the result of the changes he made to the original Varga. After the new "Montanair

Spirit" was completed and flown in September of 1988, it was decided that

there was too much risk and too little profit to proceed with production so Max

returned to his job at McDonnell Douglas in January of 1989.

In

December of 1987 Max moved to Montana with his family to build Varga airplanes

again. His first task was to modernize the design. The following pictures are

the result of the changes he made to the original Varga. After the new "Montanair

Spirit" was completed and flown in September of 1988, it was decided that

there was too much risk and too little profit to proceed with production so Max

returned to his job at McDonnell Douglas in January of 1989.

This right front view of the Montanair "Spirit" shows some of the changes from the original Varga model that were made to the nose of the airplane. The spinner is a duplicate of a 14" diameter unit used on a Piper Cherokee 180. The Varga has a 12" diameter spinner from the Piper Cherokee 140. The "Spirit" propeller is also the same as that used on the Cherokee 180, which is a 76" Sensenich with a 60" pitch a 1.25" spacer. The Varga 2180 has a 76" diameter 60" pitch Sensenich propeller without a spacer. The nose cowl is similar in construction to the original Varga, but the fiberglass nose bowl is Max's own design and the firewall shape was changed to make the cowl fit better around the 0-360 180 hp Lycoming engine.

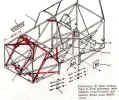

This

drawing shows the 3 inch fuselage stretch forward of the wing leading edge.

This stretching and lowering of the forward pedals 1.5" added significantly

more leg room for the pilot. The forward pedals given a 4" adjustment range

to accommodate both short and tall pilots.

This

drawing shows the 3 inch fuselage stretch forward of the wing leading edge.

This stretching and lowering of the forward pedals 1.5" added significantly

more leg room for the pilot. The forward pedals given a 4" adjustment range

to accommodate both short and tall pilots.

This

left side view shows the shape of the canopy and the new vertical tail. The

original canopy frame shape was retained to make retrofitting easier. The canopy glass

was designed to be tallest at the pilots head and the same height as the

original Varga above the passengers head. The vertical tail was moved aft more

than two feet and and rudder area added below the horizontal tail in an effort

to improve spin recovery. The dorsal fin was added only for appearance. (It

should be noted that, as certified, the original Varga WILL NOT SPIN (OK, maybe

a stalled spiral), but during Varga 2180 certification flight testing several

degrees of increased elevator travel were added and we experienced an

unrecoverable spin. The extra elevator travel was removed and spin tests

proceeded without incident.)

This

left side view shows the shape of the canopy and the new vertical tail. The

original canopy frame shape was retained to make retrofitting easier. The canopy glass

was designed to be tallest at the pilots head and the same height as the

original Varga above the passengers head. The vertical tail was moved aft more

than two feet and and rudder area added below the horizontal tail in an effort

to improve spin recovery. The dorsal fin was added only for appearance. (It

should be noted that, as certified, the original Varga WILL NOT SPIN (OK, maybe

a stalled spiral), but during Varga 2180 certification flight testing several

degrees of increased elevator travel were added and we experienced an

unrecoverable spin. The extra elevator travel was removed and spin tests

proceeded without incident.)

The

left front view again shows the nose cowl, prop and spinner. The

carburetor air inlet box was installed in the left cooling air inlet and ducted

to a new carburetor heat box.

The

left front view again shows the nose cowl, prop and spinner. The

carburetor air inlet box was installed in the left cooling air inlet and ducted

to a new carburetor heat box.

This

close-up of the vertical tail shows the relatively large aero counter-balance,

the rudder area under the horizontal tail and the split elevator. The aero

counter-balance and elimination of the rudder centering were intended to reduce

rudder pressure, which they did. Max left Montanair before completion of their

spin testing, but his understanding is that these modifications by themselves had

little or no effect on spin recovery with increased elevator travel.

This

close-up of the vertical tail shows the relatively large aero counter-balance,

the rudder area under the horizontal tail and the split elevator. The aero

counter-balance and elimination of the rudder centering were intended to reduce

rudder pressure, which they did. Max left Montanair before completion of their

spin testing, but his understanding is that these modifications by themselves had

little or no effect on spin recovery with increased elevator travel.